F30

DIRECT DRIVE TROWEL

From Float to Finish it’s still the Master

Features and Benefits:

Direct Drive Means:

- Low Center Of Gravity

- No Belt To Adjust

- Less Wobble And Side Torque

- Increased Power to Gearbox And Spider ! Longer Blade Life

- Only Direct-Drive Trowel In The Industry

- Fully Enclosed Blade-Pitch Mechanism

- Electric Deadman Switch For Safety

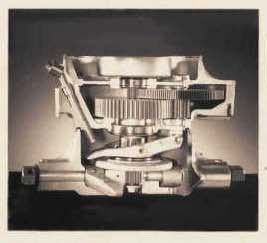

- Heavy-Duty Gearbox Standard

What Direct-Drive Means to the Professional Finisher

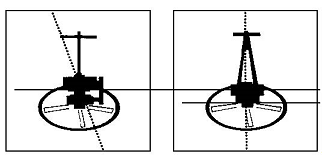

Conventional Belt Drive: Direct - Drive:

Has a high center of gravity and an unbalanced Has a low center of gravity and balanced power transfer of power from the engine to belt to transfer which means a smoother, flatter finish gear box to with easier blades which handling. creates wobble and a loss of power.

Belt Drive COG  Direct Drive COG

Direct Drive COG

The unique enclosed spider assembly eliminates concrete build-up around gearbox and pitch control mechanism.

Electric deadman switch insures operator safety and security.

F36 & 46

DIRECT DRIVE TROWEL

From Float to Finish it’s still the Master

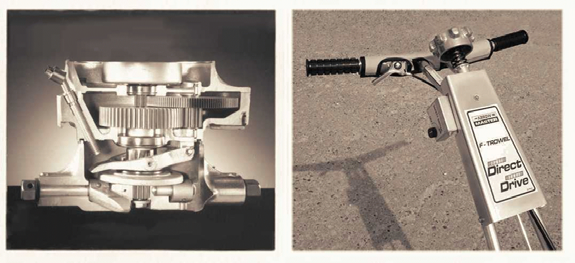

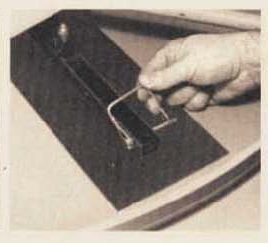

The Unique Enclosed Spider

assembly eliminates concrete build-up

around gearbox and pitch control assembly

Blade Replacement Clips

are easily removed for quick maintenance

and changing of channel mount blades